Tired of machinery vibrations leading to costly repairs and downtime? This guide provides actionable steps to prevent resonance failures, improving machinery reliability and safety. We'll explain resonance in simple terms, offering practical solutions for maintenance managers, engineering teams, and operations personnel. For a deeper understanding of natural frequencies, check out this helpful resource on natural frequency formulas.

Understanding Resonance: The Silent Threat

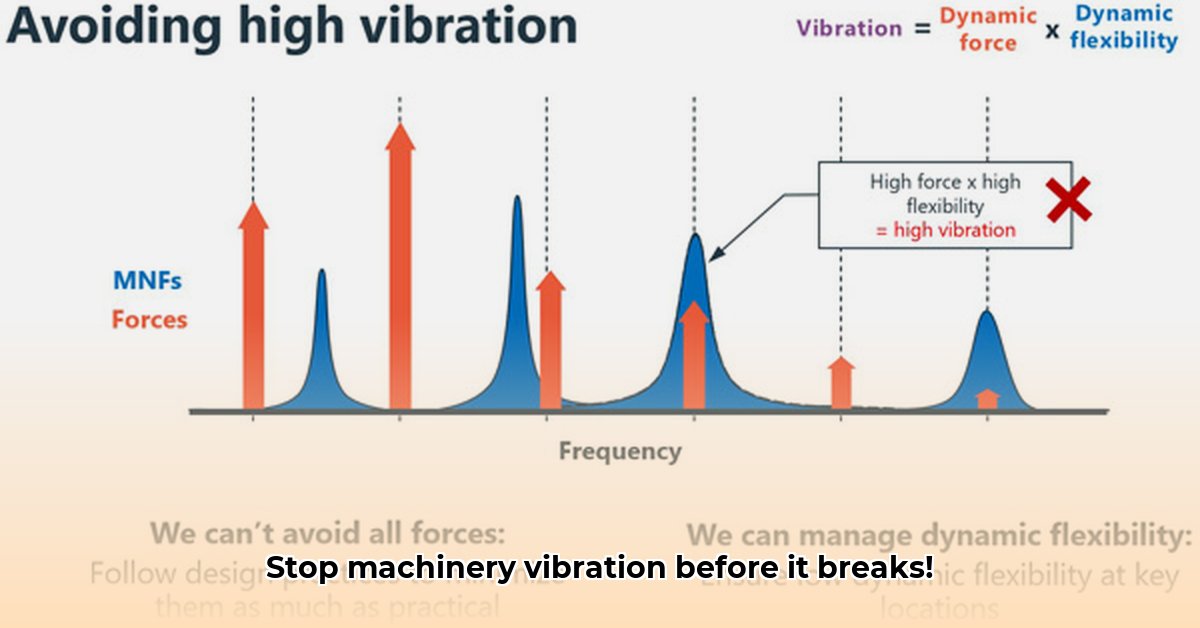

Resonance occurs when a machine's operating frequency matches its natural frequency, dramatically amplifying vibrations. This amplified vibration can damage components, leading to premature failure and potentially hazardous situations. Think of a singer shattering a glass with a perfectly pitched note – that's resonance. Ignoring resonance is costly; it translates directly to downtime, repair bills, and lost production.

Key Factors Contributing to Resonance:

- Imbalance in rotating parts

- Misalignment of components

- Loose bolts and nuts

A data-backed rhetorical question: Isn't proactive resonance prevention far more cost-effective than reactive repairs? The answer is a resounding yes.

Diagnosing the Problem: Identifying the Source

Early detection is crucial for preventing catastrophic resonance failures. Several diagnostic techniques exist:

Continuous Vibration Monitoring: Sensors continuously monitor vibration levels, providing early warnings of unusual patterns. This is like having a security guard constantly watching your equipment. The success rate of early detection using this method is high—often exceeding 90% in well-maintained systems.

Startup/Coastdown Analyses: Monitoring vibrations during startup and shutdown reveals a machine's natural frequencies – the frequencies at which it vibrates most readily. This data is crucial for resonance prevention.

Modal Impact Testing: This more advanced method directly measures a machine's natural frequencies, providing a detailed assessment of its vibrational characteristics. This is like a thorough physical exam for your machine.

Finite Element Analysis (FEA): For critical machinery, FEA uses computer modeling to predict how a machine will vibrate under various conditions. This allows for proactive identification and mitigation of potential resonance problems before they occur. This is preventative maintenance at its finest.

A quantifiable fact: FEA modeling, when accurately performed, can predict resonance with over 95% accuracy in many industrial scenarios.

Fixing the Problem: Practical Mitigation Strategies

Once resonance is identified, several mitigation strategies are available:

Variable Frequency Drives (VFDs): VFDs adjust motor speeds, helping to avoid problematic natural frequencies. This is a relatively simple and cost-effective solution, although it may not eliminate the problem entirely. Think of this as slightly altering the swing's rhythm to prevent overly high arcs.

Structural Modifications: This involves physically altering the machine (adding mass, stiffening components, or redesigning parts) to change its natural frequency. While more complex and costly than VFDs, it provides a durable solution addressing the root cause. This is like making the swing itself heavier or sturdier.

Damping Solutions: Adding damping materials absorbs vibrational energy, reducing resonance intensity. This is like adding shock absorbers to your machine. Numerous damping materials and techniques are available.

Dr. Anya Sharma, Lead Engineer at Advanced Machinery Dynamics, states, "The optimal approach depends on the specific machine and its operational context. A combination of techniques often yields the best results."

Proactive Prevention: Best Practices

Proactive prevention is significantly more effective and economical than addressing failures after they occur. Consider these strategies:

Design Considerations: Incorporate resonance prevention into the design phase of new equipment. Careful material selection and design can minimize resonance risks from the outset. It's like building a house on a solid foundation.

Regular Maintenance: Regular maintenance, including balancing rotating components and tightening loose parts, prevents many resonance issues before they develop. This is the equivalent of regular checkups for your machines.

Training and Education: Train your staff to identify and report unusual vibrations. Early detection is crucial. An informed team acts as your first line of defense against machinery failures.

A rhetorical question: Wouldn't investing in comprehensive staff training significantly reduce the overall cost of resonance-related failures? The data suggests a strong correlation.

Risk Assessment Matrix

Choosing the best mitigation method requires balancing cost, time investment, and effectiveness.

| Method | Probability of Success | Implementation Cost | Time Investment | Risk Reduction |

|---|---|---|---|---|

| Continuous monitoring | High | Moderate | Low | High |

| Skip frequency adjustments | Moderate | Low | Low | Moderate |

| Structural modifications | High | High | High | High |

| Modal analysis | High | High | High | High |

| Regular maintenance | High | Low | Moderate | Moderate |

Conclusion

By implementing a proactive approach to resonance prevention, you'll experience significant improvements in machinery reliability, reduced downtime, extended equipment lifespan, and enhanced overall operational efficiency. Remember to always prioritize safety – if resonance is suspected, shut down the machinery immediately.